Thermometer for Environment Temperature and Humidity Check

- The Importance of Accurate Temperature Control:

- Best Practices for Humidity Management:

Maintaining the right temperature is crucial for paint application. Fluctuations can affect drying times and the final finish.

High humidity can cause paint to dry slowly or not adhere properly, while low humidity can lead to premature drying and poor coverage.

Surface Thermometer (Dial Type with Magnet)

- Understanding Surface Temperature Impact:

- How Magnetized Surface Thermometers Simplify Readings:

Surface temperature influences paint viscosity and adhesion. It's vital for achieving optimal results.

Magnetic surface thermometers offer convenience by securely attaching to surfaces, ensuring accurate temperature readings.

Hygrometer for Dew Point Check

- Dew Point and its Role in Painting:

- Using a Hygrometer for Precise Dew Point Assessment:

Dew point is the temperature at which air becomes saturated with moisture, affecting paint drying times and adhesion.

Hygrometers help painters determine if conditions are suitable for painting by measuring relative humidity and dew point.

Salt Test Kit in Compliance with ISO 8502-6 and ISO 8502-9 (Bresle Kit)

- Why Salt Tests Matter in External Painting:

- Interpreting Results According to ISO Standards:

Salt contamination on surfaces can lead to coating failure. Salt tests ensure surfaces are adequately prepared for painting.

Salt test results are interpreted following ISO standards to determine if surfaces meet required cleanliness levels.

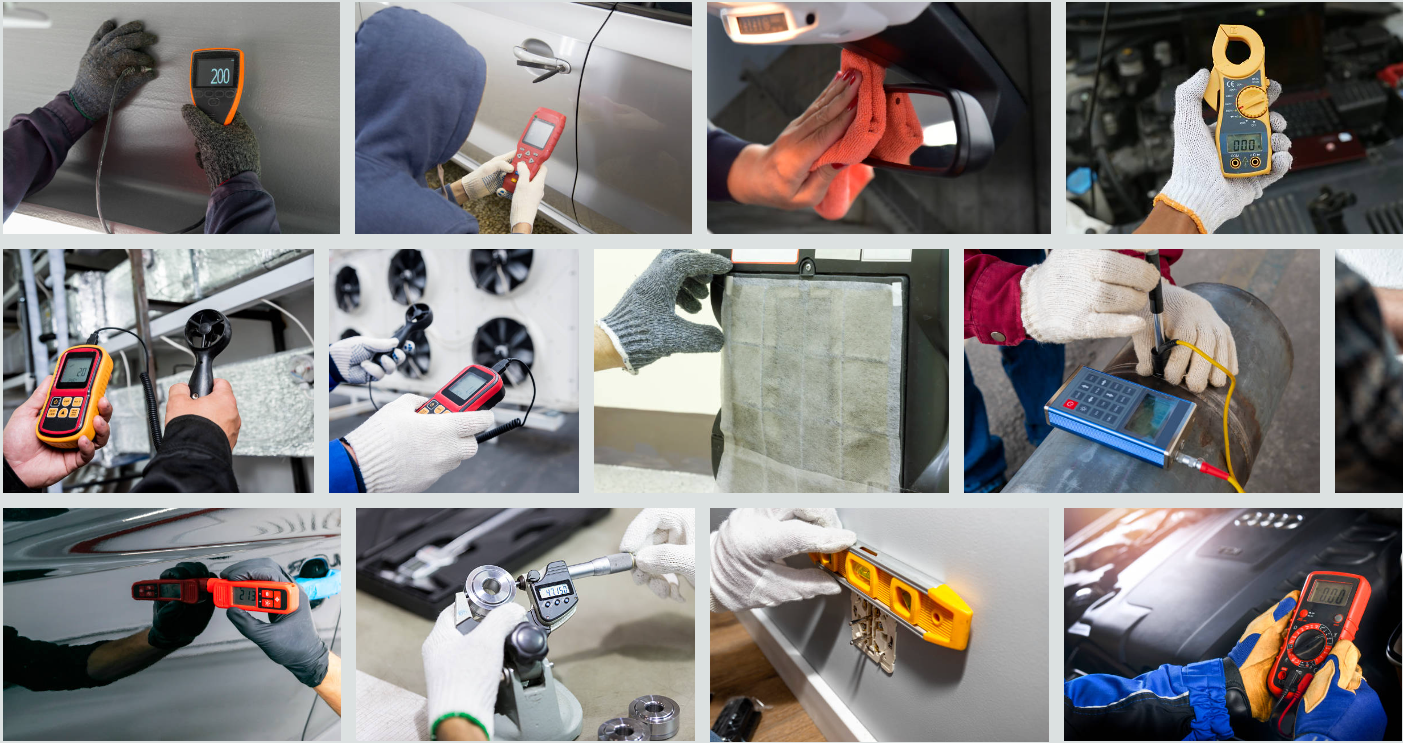

Surface Profile Gauge

- The Significance of Surface Profiling:

- Achieving the Ideal Surface Profile for Paint Adhesion:

Surface profile affects paint adhesion and coating durability. Measuring it ensures proper surface preparation.

Surface profile gauges help painters assess surface roughness and ensure it meets paint manufacturer specifications.

Comparator to Check Surface Roughness

- Assessing Surface Roughness for Optimal Painting:

- Tips for Effective Use of Surface Roughness Comparators:

Surface roughness affects paint adhesion and appearance. Comparators help evaluate surface texture for painting suitability.

Proper lighting and positioning are essential for accurate surface roughness assessment using comparators.

Comparator to Check Surface Preparation/Cleanliness Check as per ISO 8501-1

- Adhering to ISO Standards for Surface Cleanliness:

- Ensuring Adequate Surface Preparation:

ISO 8501-1 outlines surface preparation standards to ensure proper coating adhesion and longevity.

Comparators verify surface cleanliness, helping painters adhere to ISO standards and achieve desired paint performance.

MEK Test Kit

- MEK Testing: A Crucial Step in Surface Evaluation:

- Interpreting Results for Material Compatibility:

Methyl Ethyl Ketone (MEK) tests determine coating resistance and adhesion, providing insights into surface condition.

MEK test results indicate coating integrity and compatibility with substrates, guiding paint selection and application.

Holiday Test Kit (Wet Sponge Method)

- Detecting Coating Imperfections with the Wet Sponge Method:

- Addressing Holiday Detection Challenges:

Holiday tests identify pinholes, cracks, or other coating defects invisible to the naked eye, ensuring quality finishes.

Proper sponge saturation and pressure application are critical for accurate holiday detection and preventing premature coating failure.

Adhesion Test Kit (Pull-off/Dolly Test) in Compliance with ISO 4624

- The Significance of Adhesion Testing in Painting:

- Meeting ISO 4624 Standards for Adhesion:

Adhesion tests evaluate paint bond strength to substrates, ensuring coatings withstand environmental stresses and adhere properly.

Adhesion test kits follow ISO 4624 protocols to assess paint adhesion quality, helping maintain industry standards.

Cross-cut Test Kit

- Understanding Cross-Cut Testing for Coating Durability:

- Interpreting Results and Addressing Issues:

Cross-cut tests assess paint adhesion and resistance to cracking or flaking, crucial for ensuring coating durability.

Cross-cut test results determine coating adhesion quality, guiding corrective actions to prevent premature coating failure.

Testex Press-O-Film (Course & Non-Course)

- Using Press-O-Film for Reliable Coating Thickness Measurement:

- Choosing the Right Grade for Your Project:

Press-O-Film ensures consistent and accurate coating thickness measurement, vital for achieving desired paint performance and durability.

Selecting the appropriate Press-O-Film grade ensures precise measurement according to coating thickness requirements and substrate conditions.

Needle Pressure Gauge (15 Bar)

- Needle Pressure Gauges:

- Ensuring Accuracy in Pressure Measurement:

A Critical Component in Pressure Testing: Needle pressure gauges accurately measure pressure, ensuring paint application and equipment operate within safe limits.

Calibrating needle pressure gauges and verifying accuracy before use is essential for reliable pressure testing and optimal paint application.

Boltter Paper

- The Role of Boltter Paper in Surface Preparation:

- Tips for Effective Use in Painting Projects:

Boltter paper removes contaminants and residues from surfaces, promoting proper adhesion and paint film integrity.

Proper technique, such as consistent pressure and direction, ensures thorough surface cleaning with boltter paper, enhancing paint performance.

Gauge to Check WFT (CS & SS)

- Wet Film Thickness:

- Using Gauges for Accurate WFT Measurement:

Understanding its Impact on Coating Quality: Wet film thickness influences paint coverage, drying times, and final coating appearance, requiring accurate measurement for quality assurance.

Wet film thickness gauges ensure consistent paint application thickness, preventing under or over-application and achieving desired coating properties.

Gauge to Check DFT (CS & SS)

- Dry Film Thickness: Ensuring Compliance with Standards:

- Using Gauges for Precise DFT Measurement:

Dry film thickness affects coating performance and longevity. Gauges verify thickness levels, ensuring adherence to industry standards and specifications.

Proper gauge selection and calibration are essential for accurate dry film thickness measurement, ensuring coatings meet performance requirements and durability expectations.

0 Comments