What Does Holiday Test Mean?

When it comes to protecting metal surfaces from corrosion, a holiday test is an important step in ensuring the effectiveness of an anticorrosive surface coating. But what exactly does the term "holiday test" refer to?

A holiday test, also known as a "spark test" or "voltage holiday test," is a method for detecting discontinuities or defects in a coating. These defects can include:

- A discontinuity in coating, when a part of the surface remains uncoated

- A defect such as an area of insufficient coating film thickness

- A pinhole within the coating

- A crack within the coating

- An improper adhesion or bonding of the coating

You might be interested in :

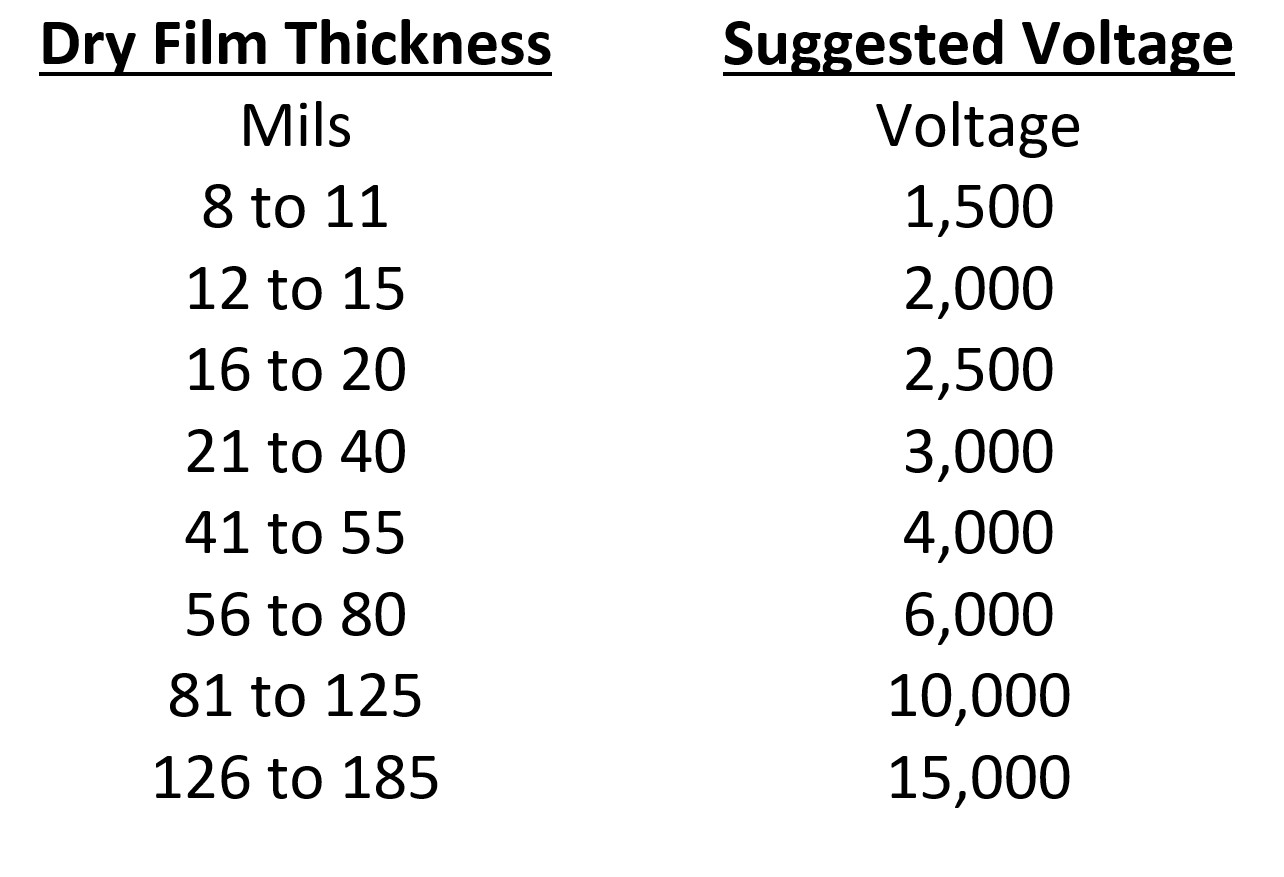

During a holiday test, a low voltage current is passed through the coating. Any discontinuities or defects in the coating will create a spark or "holiday," indicating the location of the problem. This allows for quick and easy detection and repair of any issues with the coating, ensuring maximum effectiveness in protecting the metal surface from corrosion.

It's important to note that holiday test is only one of the several methods to check the coating quality and should be combined with other methods for a complete inspection. Other methods include visual inspection, dry film thickness measurement, adhesion test, and salt spray test etc. These methods are complementary to each other and provide a comprehensive assessment of the coating quality.

It's also important to note that the holiday test should be performed by certified professionals who are trained to use the equipment and interpret the results correctly. Improperly performed holiday tests can lead to false readings and inaccurate conclusions about the coating quality.

Conclusion

In conclusion, a holiday test is a valuable tool for ensuring the quality and effectiveness of an anticorrosive surface coating. By detecting defects and discontinuities in the coating, a holiday test can help to extend the life of the metal surface and protect it from the damaging effects of corrosion. It should be combined with other inspection methods, and performed by trained professionals for accurate results.

0 Comments