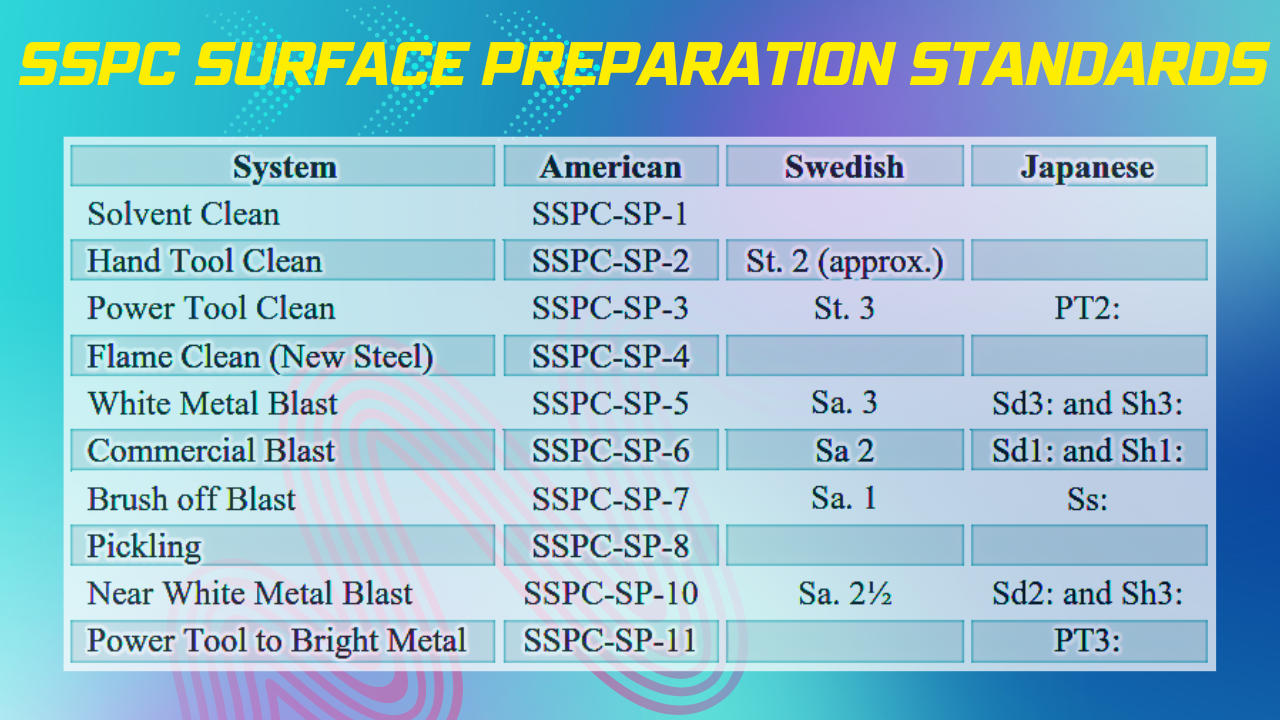

SSPC Surface Preparation Standards

When it comes to ensuring the longevity and performance of steel structures, proper surface preparation is of paramount importance. The Steel Structures Painting Council (SSPC) has developed a set of surface preparation standards that define the methods, techniques, and quality requirements for preparing steel surfaces before applying protective coatings. These standards provide a comprehensive framework for achieving optimal coating adhesion and durability.

In this article, we will delve into the various SSPC surface preparation standards, including:

We will explore the techniques, benefits, and best practices associated with each standard, providing you with valuable insights to enhance your knowledge of steel cleaning.

SSPC-SP1 Solvent Cleaning

SSPC-SP1 Solvent Cleaning is a surface preparation standard that involves the use of solvents to remove contaminants such as oil, grease, dirt, and loose rust from steel surfaces. This method is typically employed when the level of surface cleanliness required is less stringent, and where other methods like abrasive blasting may not be feasible or practical.

Benefits of SSPC-SP1 Solvent Cleaning

Solvent cleaning offers several advantages in the surface preparation process. Firstly, it is a relatively simple and cost-effective method compared to more abrasive techniques. Solvent cleaning can be accomplished using a variety of solvents, making it adaptable to different project requirements. Additionally, this method is non-destructive and does not create any surface profile, making it suitable for situations where maintaining the original surface profile is crucial.

Best Practices for SSPC-SP1 Solvent Cleaning

To ensure effective solvent cleaning, it is important to follow a few best practices. Start by selecting the appropriate solvent based on the type and extent of contaminants present on the surface. Perform a small test area to verify the effectiveness of the selected solvent. When applying the solvent, use clean, lint-free rags or brushes to minimize the introduction of additional contaminants. Proper ventilation is essential to ensure the safety of workers and prevent the accumulation of solvent vapors.

SSPC-SP2 Hand Tool Cleaning

SSPC-SP2 Hand Tool Cleaning is a surface preparation standard that involves the use of hand tools such as wire brushes, scrapers, and sandpaper to remove loose rust, mill scale, and old coatings from steel surfaces. This method is commonly employed in areas where power tools cannot reach or in situations where abrasive blasting is not practical.

Benefits of SSPC-SP2 Hand Tool Cleaning

Hand tool cleaning offers several benefits for surface preparation. It allows for localized treatment and precise removal of contaminants, ensuring thorough cleaning. This method is highly versatile and can be used on irregular surfaces, corners, and edges. Hand tool cleaning is also a viable option for small-scale projects or touch-up work.

Best Practices for SSPC-SP2 Hand Tool Cleaning

To achieve optimal results with hand tool cleaning, it is important to follow best practices. Select the appropriate hand tools based on the nature and extent of the contaminants. Use wire brushes with suitable bristle stiffness for effective cleaning. Scrapers and sandpaper can be employed to remove tightly adherent rust or coatings. After cleaning, remove all residue and loose particles using clean brushes or compressed air. Finally, ensure proper containment and disposal of debris to maintain a clean and safe work environment.

SSPC-SP3 Power Tool Cleaning

SSPC-SP3 Power Tool Cleaning is a surface preparation standard that involves the use of power tools such as power sanders, grinders, and wire brushes to remove loose rust, mill scale, and old coatings from steel surfaces. This method is particularly useful for large-scale projects where abrasive blasting may not be feasible or economical.

Benefits of SSPC-SP3 Power Tool Cleaning

Power tool cleaning offers several advantages in surface preparation. It allows for efficient and rapid removal of contaminants, reducing the overall project time. Power tools provide greater control and productivity compared to hand tools, making them suitable for large surface areas. This method also minimizes the generation of dust and airborne particles, enhancing worker safety.

Best Practices for SSPC-SP3 Power Tool Cleaning

To ensure effective power tool cleaning, it is crucial to follow best practices. Select the appropriate power tool and abrasive attachment based on the project requirements and surface conditions. Ensure that the power tool is in good working condition and has the necessary safety features. Employ proper dust collection systems to minimize the release of airborne particles. Regularly inspect the abrasive attachment for wear and replace it as needed. Finally, clean the surface thoroughly after power tool cleaning to remove any residual debris.

SSPC-SP5 White Metal Blast Cleaning

SSPC-SP5 White Metal Blast Cleaning is a surface preparation standard that involves the use of abrasive blasting to remove all visible rust, mill scale, and old coatings from steel surfaces. This method achieves the highest degree of surface cleanliness, producing a white metal surface with a uniform, fine texture.

Benefits of SSPC-SP5 White Metal Blast Cleaning

White metal blast cleaning offers numerous benefits for surface preparation. It provides an optimal surface profile for coating adhesion, ensuring long-lasting performance. This method effectively removes all contaminants, including tightly adherent rust and coatings, leaving a clean, uniform surface. White metal blast cleaning is particularly suitable for critical applications where the highest level of surface cleanliness is required.

Best Practices for SSPC-SP5 White Metal Blast Cleaning

To achieve the desired results with white metal blast cleaning, it is essential to adhere to best practices. Select the appropriate abrasive media, such as steel shot or grit, based on the surface condition and project specifications. Adjust the blasting parameters, including pressure and distance, to achieve the desired surface profile. Regularly inspect the blast cleaning equipment to ensure proper functioning and prevent the introduction of contaminants. Implement proper containment and cleanup procedures to minimize environmental impact. Finally, verify the achieved surface cleanliness using visual inspection or other appropriate methods.

SSPC-SP6 Commercial Blast Cleaning

SSPC-SP6 Commercial Blast Cleaning is a surface preparation standard that involves the use of abrasive blasting to remove visible rust, mill scale, and old coatings from steel surfaces. This method provides a thorough cleaning while allowing for a slight degree of staining, discoloration, or shadows.

Benefits of SSPC-SP6 Commercial Blast Cleaning

Commercial blast cleaning offers several advantages for surface preparation. It provides a suitable surface profile for coating adhesion while allowing for a controlled degree of staining. This method effectively removes contaminants, including rust and coatings, ensuring a clean and uniform surface. Commercial blast cleaning is commonly used in non-critical applications where slight discoloration or shadows are acceptable.

Best Practices for SSPC-SP6 Commercial Blast Cleaning

To achieve optimal results with commercial blast cleaning, it is important to follow best practices. Select the appropriate abrasive media based on the surface condition and project requirements. Adjust the blasting parameters to achieve the desired surface profile and cleanliness. Regularly inspect the blasting equipment and abrasive media to ensure proper functioning and quality. Implement adequate containment measures to minimize the spread of dust and debris. Finally, clean the surface thoroughly after blasting to remove any residual contaminants.

SSPC-SP10 Near-White Blast Cleaning

SSPC-SP10 Near-White Blast Cleaning is a surface preparation standard that involves the use of abrasive blasting to remove visible rust, mill scale, and old coatings from steel surfaces. This method achieves a higher degree of cleanliness compared to commercial blast cleaning, with a surface that appears predominantly white or gray, with slight staining or shadows.

Benefits of SSPC-SP10 Near-White Blast Cleaning

Near-white blast cleaning offers several benefits for surface preparation. It provides a surface profile that enhances coating adhesion and durability. This method effectively removes rust, mill scale, and coatings, leaving a predominantly clean and uniform surface. Near-white blast cleaning is commonly used in applications where a higher degree of cleanliness is required, but strict white metal standards are not necessary.

Best Practices for SSPC-SP10 Near-White Blast Cleaning

To achieve the desired results with near-white blast cleaning, it is crucial to follow best practices. Select the appropriate abrasive media and adjust the blasting parameters to achieve the desired surface profile and cleanliness. Regularly inspect the blasting equipment and abrasive media for proper functioning and quality. Implement effective containment and cleanup procedures to minimize environmental impact. Finally, conduct visual inspections or other appropriate tests to verify the achieved surface cleanliness.

SSPC-SP12/NACE No. 5

SSPC-SP12/NACE No. 5 Surface Preparation and Cleaning of Steel and Other Hard Materials by High- and Ultrahigh-Pressure Waterjetting Prior to Recoating SSPC-SP12/NACE No. 5 is a surface preparation standard jointly developed by SSPC and the National Association of Corrosion Engineers (NACE). It involves the use of high- and ultrahigh-pressure waterjetting to remove coatings, rust, and other contaminants from steel and other hard materials. This method utilizes the power of pressurized water to achieve a clean, profiled surface.

Benefits of SSPC-SP12/NACE No. 5 Waterjetting

Waterjetting offers several advantages for surface preparation. It is a versatile method that can be used on various substrates, including steel, concrete, and masonry. Waterjetting effectively removes coatings, rust, and other contaminants without generating dust or introducing additional contaminants. This method is suitable for sensitive environments where other surface preparation methods may not be practical.

Best Practices for SSPC-SP12/NACE No. 5 Waterjetting

To ensure effective waterjetting, it is important to follow best practices. Select the appropriate waterjetting equipment, including pumps, nozzles, and hoses, based on the project requirements and surface conditions. Adjust the water pressure, flow rate, and standoff distance to achieve the desired surface cleanliness and profile. Ensure that the water used for jetting is clean and free from contaminants. Implement proper containment and collection systems to manage the wastewater and prevent environmental contamination. Finally, verify the achieved surface cleanliness using visual inspection or other appropriate methods.

Conclusion

Proper surface preparation is a critical step in achieving long-lasting and durable coatings on steel structures. The SSPC surface preparation standards provide a comprehensive set of guidelines and techniques for cleaning steel surfaces based on specific project requirements. Whether it is solvent cleaning, hand tool cleaning, power tool cleaning, abrasive blasting, or waterjetting, each method has its own benefits and best practices.

By understanding and implementing the appropriate SSPC surface preparation standard, you can ensure the removal of contaminants, achieve the desired surface cleanliness and profile, and enhance the performance and longevity of protective coatings on steel structures.

0 Comments