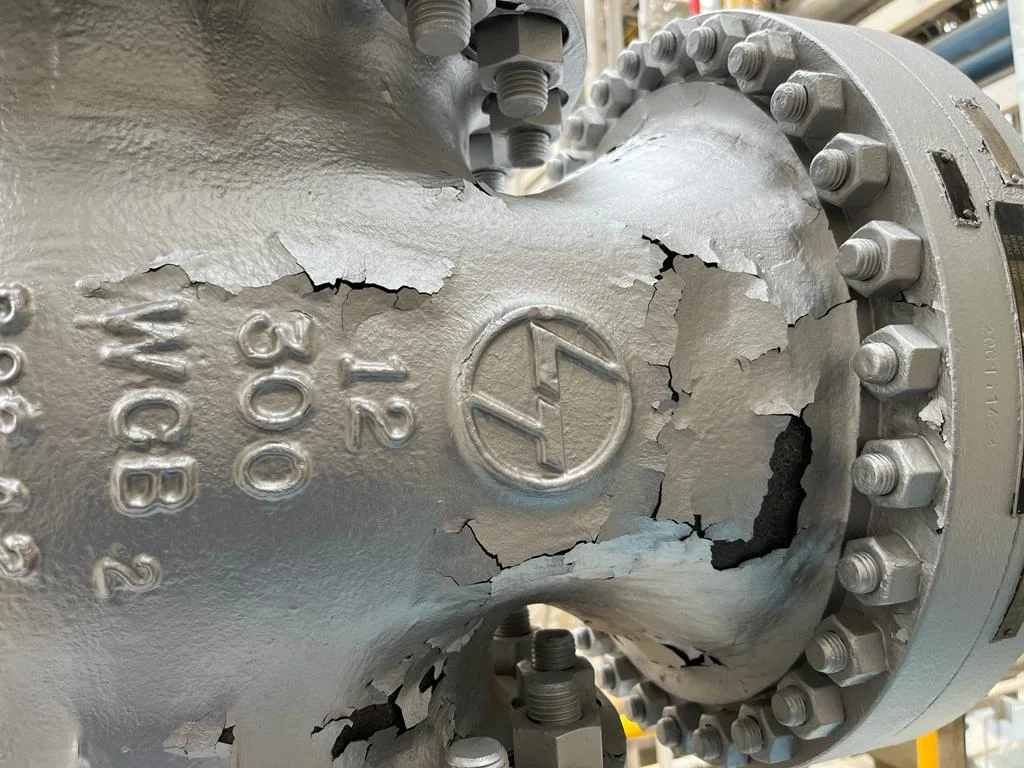

Causes of Peeling Paint.

Peeling paint from pipes and valves can occur due to various reasons related to inadequate surface preparation, moisture, compatibility of paint types, dryness, and other environmental factors. Here are the common causes of peeling paint from pipes and valves:

- Moisture and Water: One of the primary causes of peeling paint is moisture infiltration. When water gets under the paint, it compromises the paint's adhesion to the surface. This is especially common in wet areas of a building, such as bathrooms, kitchens, or areas with leaks or excess humidity. Water damage can weaken the paint's bond, leading to peeling [1].

- Inadequate Preparation – Cleaning and Priming: Proper surface preparation is crucial before painting. If a surface is not cleaned and primed correctly, dirt and debris can prevent paint from adhering properly. Applying paint over a dirty or unprimed surface can result in peeling paint [1].

- Combining Different Paint Types: Mixing incompatible paint types can lead to peeling. For instance, applying latex-based paint over oil-based paint can cause adhesion issues, resulting in paint peeling off the surface [1].

- Dryness: While moisture is a common cause of peeling, extreme dry conditions can also contribute to paint failure. Just as skin can crack when dry, paint can peel when exposed to harsh, dry environments. This is particularly relevant if the environment lacks proper humidity or moisture [1].

- Strange Surfaces: Different surfaces require specific types of paint. For example, applying paint meant for new wood on improperly cured or oily wood can lead to peeling due to poor adhesion. It's important to choose the right paint for each surface and ensure proper curing [1].

- Heavy Layering: Repeated paint applications can lead to excessive weight on the surface. Over time, the accumulated weight of paint layers can cause them to peel due to gravity's influence [1].

- Age: Paint has a limited lifespan, and over time, it naturally ages and degrades. As the paint ages, it becomes more susceptible to peeling. This aging process is a common reason for peeling paint [1].

- Surface Contamination: Dirt, grease, or other contaminants on the surface can prevent paint from adhering properly. Water-based coatings are particularly sensitive to grease and oil contamination [2].

- Surface Temperature: Applying paint to a surface that is too hot can cause the paint's solvent to evaporate too quickly. This can lead to poor adhesion as the paint doesn't have enough time to properly bond with the surface [2].

- Compatibility of Coatings: Using coatings that are not compatible with the substrate or with existing coatings can result in chemical reactions that break down adhesion bonds, causing peeling [2].

- Surface Smoothness: A lack of surface profile can prevent mechanical adhesion between the paint and the substrate. Surfaces that are too smooth may not provide enough texture for the paint to adhere properly [2].

Source URL

How to prevent peeling paint and ensure proper adhesion for a lasting finish.

Guidance: To safeguard against the issue of peeling paint, particularly in the context of pipes and valves, meticulous attention must be directed towards the following pivotal facets:

- Comprehensive Surface Preparation: Attaining optimal adhesion necessitates a thorough and precise surface preparation regimen. Prior to commencing any paint application, ensure that the substrate is meticulously cleaned and primed. Any contaminants or imperfections on the surface can significantly compromise paint adherence.

- Selection of Appropriate Paint System: The choice of a suitable paint system is of paramount significance. Compatibility between the chosen paint type and the substrate must be meticulously established. Moreover, special consideration should be given to factors such as environmental conditions, exposure, and intended usage.

- Mitigation of Moisture Concerns: Vigilance regarding moisture infiltration is non-negotiable. Addressing any potential sources of moisture or water ingress, especially in areas prone to dampness or humidity, is vital to ensure the longevity of the coating. Diligent measures should be taken to rectify leaks, excess humidity, or inadequate sealing.

- Adherence to Industry-Approved Practices: To achieve a durable and robust coating, adherence to industry-approved painting practices is paramount. Following established guidelines for application techniques, drying times, and layering is crucial to minimize the risk of paint peeling and to maximize the coating's performance over time.

In sum, a comprehensive approach encompassing meticulous surface preparation, judicious paint system selection, vigilant moisture management, and strict adherence to industry-best practices is the bedrock for the effective prevention of paint peeling from pipes and valves. By embodying these principles, we can ensure the sustained integrity and performance of coatings in critical applications.

0 Comments