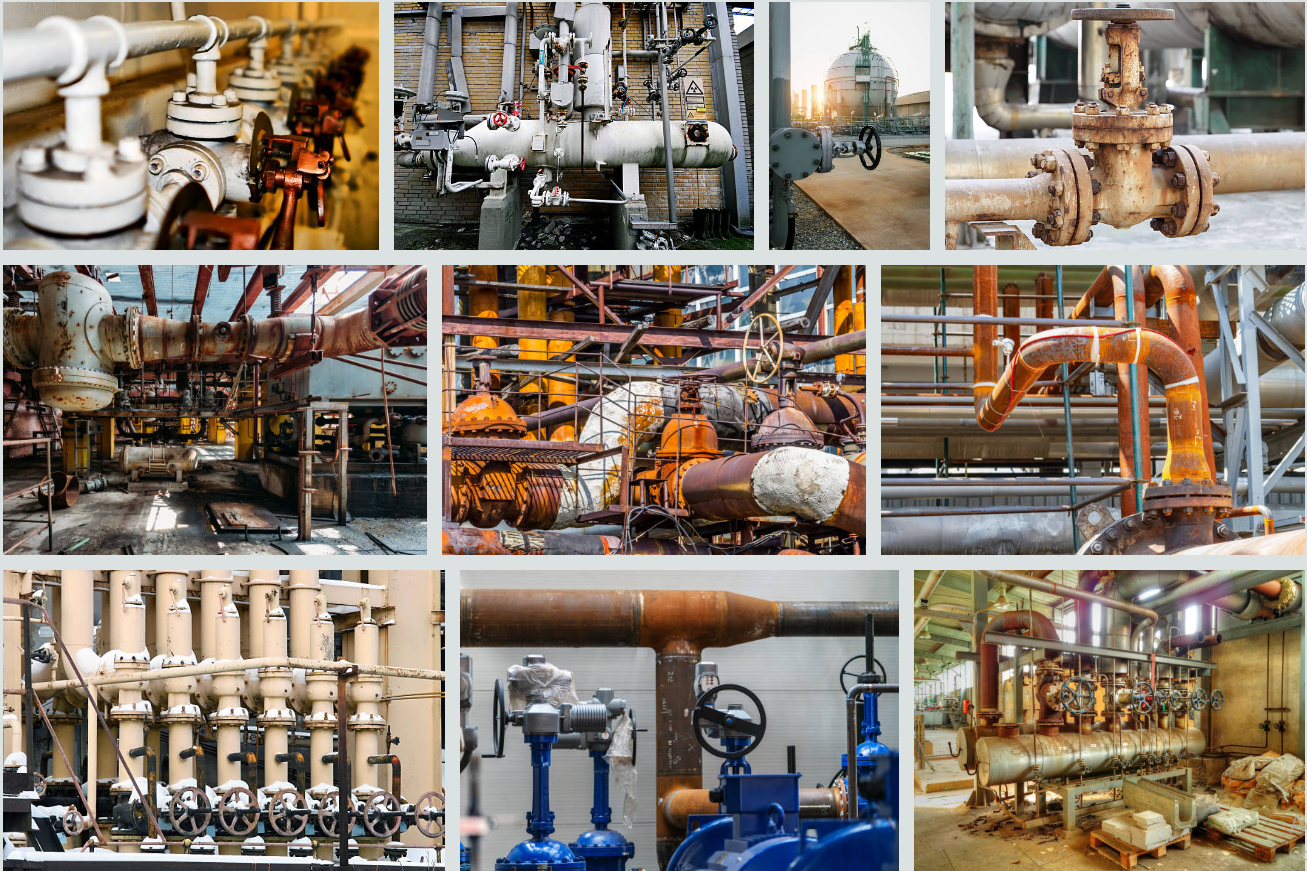

Types of Corrosion: Understanding the Different Forms of Metal Deterioration

Corrosion is the gradual destruction of materials, typically metals, due to chemical reactions with their environment. It is a natural process that occurs in various forms, each with its own unique characteristics and causes. Understanding the different types of corrosion is important for preventing and managing it in various industries, including construction, transportation, and manufacturing.

Uniform Corrosion

Uniform corrosion is the most common form of corrosion and occurs when the entire surface of a metal is affected evenly. It is often caused by exposure to moist environments, such as saltwater or high humidity. This type of corrosion is characterized by a uniform loss of metal thickness over the entire surface and can be prevented by using corrosion-resistant materials or applying protective coatings.

Pitting Corrosion

Pitting corrosion is a localized form of corrosion that occurs in small, isolated areas on a metal surface. It is caused by the concentration of corrosive agents in specific areas, such as in crevices or on surfaces with defects. Pitting corrosion can be particularly harmful as it can weaken a metal's structural integrity and can lead to premature failure. It can be prevented by using corrosion-resistant materials, controlling the environment, and by regular inspections and maintenance.

Galvanic Corrosion

Galvanic corrosion occurs when two different types of metals are in contact with each other and an electrolyte, such as water, is present. The more active metal corrodes faster, while the less active metal corrodes slower. This type of corrosion can be prevented by using corrosion-resistant materials and by separating dissimilar metals with a barrier, such as paint or a plastic coating.

Stress Corrosion Cracking

Stress corrosion cracking (SCC) occurs when a metal is subjected to both a tensile stress and a corrosive environment. It is most common in metals that are already weakened by other forms of corrosion, such as pitting. SCC can lead to sudden and unexpected failures and can be prevented by using corrosion-resistant materials, controlling the environment, and by regular inspections and maintenance.

Crevice Corrosion

Crevice corrosion is a localized form of corrosion that occurs in small, confined spaces, such as gaps, crevices, or under gaskets and seals. These confined spaces can trap corrosive agents and prevent the circulation of oxygen, leading to an increased concentration of corrosive agents and accelerated corrosion. Crevice corrosion can be particularly harmful as it can weaken a metal's structural integrity and can lead to premature failure. It can be prevented by using corrosion-resistant materials, controlling the environment, and by regular inspections and maintenance, ensuring that these confined spaces are kept clean and free of debris.

Intergranular Corrosion

Intergranular corrosion, also known as grain boundary corrosion, occurs at the boundaries between grains in a metal. It is caused by the presence of impurities, such as sulfur, phosphorus, or carbon, at the grain boundaries. These impurities can cause a difference in the corrosion behavior of the metal at the grain boundaries compared to the rest of the metal. Intergranular corrosion can lead to cracking and failure of the metal and can be prevented by using corrosion-resistant materials, controlling the environment and by using proper heat treatment during the manufacturing process to minimize the presence of impurities at the grain boundaries.

Conclusion

Corrosion is a natural process that can cause significant damage to metal structures and equipment. Understanding the different types of corrosion is important for preventing and managing it in various industries. By using corrosion-resistant materials, controlling the environment, and by regular inspections and maintenance, the effects of corrosion can be minimized.

0 Comments