How can one identify and diagnose coating faults and paint defects?

1 : Coating Faults and Paint Defects:Bleeding

Bleeding is a type of coating fault or paint defect that occurs when the coating or paint is not properly applied or is not compatible with the surface it is being applied to. This can cause the coating or paint to "bleed" through, resulting in a discoloration or staining of the surface.

There are several causes of bleeding in coatings and paint, such as:

- Using a coating or paint that is not compatible with the surface it is being applied to.

- Not properly preparing the surface before applying the coating or paint.

- Applying the coating or paint in high humidity or high temperature conditions.

- Using a coating or paint that has expired or been stored improperly.

2 : Coating Faults and Paint Defects: Blistering

Blistering is a type of coating fault or paint defect that occurs when bubbles or raised areas appear on the surface of the coating or paint. These bubbles or raised areas are caused by the release of gases or solvents trapped beneath the coating or paint. Blistering can cause the coating or paint to lose its protective properties and can lead to premature failure of the coating system.

Causes of Blistering

There are several causes of blistering in coatings and paint, such as:

- Applying the coating or paint over a surface that is not properly cleaned or is contaminated.

- Applying the coating or paint in high humidity or high temperature conditions.

- Applying the coating or paint too thickly or in multiple layers.

- Using a coating or paint that is not compatible with the surface it is being applied to.

Prevention of Blistering

To prevent blistering in coatings and paint, it is important to properly prepare the surface before application by cleaning and removing any contaminants. Additionally, it is important to follow the manufacturer's instructions for storage and use of the coating or paint, including recommendations for the appropriate humidity and temperature conditions for application. Applying the coating or paint at the correct thickness and in accordance with the manufacturer's instructions can also prevent blistering.

Correction of Blistering

To correct blistering in coatings and paint, the affected area may need to be removed and reapplied. In some cases, a sealer or primer can be applied to the surface to help prevent blistering from occurring in the future. It is important to note that blistering can be a sign of a more severe problem and it is recommended to consult a professional coating inspector to determine the underlying cause and the best course of action.

Conclusion

Blistering is a common coating fault or paint defect that can compromise the performance of a coating system. It is important to properly prepare the surface before application and to follow the manufacturer's instructions for storage and use of the coating or paint to prevent blistering from occurring. Regular inspections of the coating or paint surface can also help detect blistering or other coating faults or paint defects before they become a major issue.

3 : Coating Faults and Paint Defects: Blooming

Blooming is a type of coating fault or paint defect that occurs when a white or cloudy haze appears on the surface of the coating or paint. This haze is caused by the migration of a soluble substance, such as a wax or oil, from the substrate to the surface of the coating or paint. Blooming can affect the aesthetic appearance of the coating or paint and can also lead to a loss of gloss and durability.

Causes of Blooming

There are several causes of blooming in coatings and paint, such as:

- Applying the coating or paint over a surface that is not properly cleaned or is contaminated with soluble substances.

- Applying the coating or paint in humid or damp conditions.

- Using a coating or paint that is not compatible with the surface it is being applied to.

- Applying the coating or paint over a substrate that has not been properly sealed or primed.

Prevention of Blooming

To prevent blooming in coatings and paint, it is important to properly prepare the surface before application by cleaning and removing any contaminants. Additionally, it is important to follow the manufacturer's instructions for storage and use of the coating or paint, including recommendations for the appropriate humidity and temperature conditions for application. Applying a sealer or primer to the surface before coating or painting can also help prevent blooming from occurring.

Correction of Blooming

To correct blooming in coatings and paint, the affected area may need to be removed and reapplied. In some cases, the underlying substrate may need to be cleaned and sealed or primed before the coating or paint is reapplied. It is important to note that blooming can be a sign of a more severe problem and it is recommended to consult a professional coating inspector to determine the underlying cause and the best course of action.

Conclusion

Blooming is a common coating fault or paint defect that can affect the aesthetic appearance of the coating or paint and lead to a loss of gloss and durability. It is important to properly prepare the surface before application and to follow the manufacturer's instructions for storage and use of the coating or paint to prevent blooming from occurring. Regular inspections of the coating or paint surface can also help detect blooming or other coating faults or paint defects before they become a major issue.

4 : Coating Faults and Paint Defects: Brushing

Brushing is a type of coating fault or paint defect that occurs when brush marks are visible on the surface of the coating or paint. These marks are caused by the use of a brush to apply the coating or paint and can be caused by factors such as the type of brush used, the technique of the applicator, and the viscosity of the coating or paint. Brushing can affect the aesthetic appearance of the coating or paint and can also lead to a loss of gloss and durability.

Causes of Brushing

There are several causes of brushing in coatings and paint, such as:

- Using a brush with stiff or poor quality bristles.

- Applying the coating or paint with an improper technique.

- Using a coating or paint that is too thick or too thin.

- Applying the coating or paint in windy or gusty conditions.

Prevention of Brushing

To prevent brushing in coatings and paint, it is important to use a brush with high quality and soft bristles. Additionally, proper technique and experience in brushing is also important. The application of the coating or paint should be done when the weather conditions are optimal, avoiding windy or gusty conditions. It is also important to use the coating or paint at the correct viscosity and to follow the manufacturer's instructions for storage and use of the coating or paint.

Correction of Brushing

To correct brushing in coatings and paint, the affected area may need to be removed and reapplied. In some cases, a sealer or primer can be applied to the surface to help prevent brushing from occurring in the future. It is important to note that brushing can be a sign of a more severe problem and it is recommended to consult a professional coating inspector to determine the underlying cause and the best course of action.

Conclusion

Brushing is a common coating fault or paint defect that can affect the aesthetic appearance of the coating or paint and lead to a loss of gloss and durability. It is important to use high quality and soft bristles, proper technique and experience, and optimal weather conditions to prevent brushing from occurring. Regular inspections of the coating or paint surface can also help detect brushing or other coating faults or paint defects before they become a major issue.

5 : Coating Faults and Paint Defect: Bronzing

Bronzing is a paint defect that occurs when the topcoat of a painted surface appears to have a metallic or bronze-like appearance. This is usually caused by the use of certain types of metallic pigments in the paint, or by the reflection of light from an underlying surface. Bronzing can also occur when there is a problem with the application of the paint, such as improper curing or the use of an incompatible primer.

To prevent bronzing, it is important to use the correct type of paint and primer for the surface being painted, and to ensure that the paint is applied correctly and cured properly. If bronzing does occur, the affected areas may need to be sanded down and repainted.

6: Coating Faults and Paint Defect: Chalking

Chalking is a paint defect that occurs when the surface of a painted object becomes powdery and discolored. This is caused by the breakdown of the binder in the paint, which holds the pigment particles together. Chalking can be caused by a variety of factors, including exposure to UV light, high humidity, and temperature changes.

To prevent chalking, it is important to use paint that is designed for the specific conditions of the environment it will be applied in, and to properly prepare the surface before painting. If chalking does occur, the affected areas may need to be cleaned and repainted.

7 : Coating Faults and Paint Defect: Checking

Checking is a paint defect that occurs when small, crack-like lines appear on the surface of a painted object. This is caused by the contraction and expansion of the paint film due to changes in temperature and humidity, which can cause the paint to split and crack. Checking can also be caused by improper surface preparation or the use of an incompatible paint or primer.

To prevent checking, it is important to properly prepare the surface before painting, and to use paint and primer that are suitable for the specific conditions of the environment. If checking does occur, the affected areas may need to be sanded down and repainted.

8 : Coating Faults and Paint Defect: Cracking or Crazing

Cracking or crazing is a paint defect that occurs when fine, spiderweb-like cracks appear on the surface of a painted object. This is caused by the paint film contracting and expanding due to changes in temperature and humidity, which can cause the paint to split and crack. Cracking or crazing can also be caused by improper surface preparation or the use of an incompatible paint or primer.

To prevent cracking or crazing, it is important to properly prepare the surface before painting and to use paint and primer that are suitable for the specific conditions of the environment. If cracking or crazing does occur, the affected areas may need to be sanded down and repainted.

9: Coating Faults and Paint Defect: Dirt Retention

Dirt retention is a paint defect that occurs when dirt and other particles become trapped in the surface of a painted object. This can happen due to a variety of factors, such as improper surface preparation, the use of an incompatible paint or primer, or exposure to dirt and pollutants in the environment.

To prevent dirt retention, it is important to properly prepare the surface before painting, and to use paint and primer that are suitable for the specific conditions of the environment. If dirt retention does occur, the affected areas should be cleaned and repainted if necessary.

10 : Coating Faults and Paint Defect: Fading

Fading is a paint defect that occurs when the color of a painted surface becomes lighter or duller over time. This can be caused by exposure to UV light, high temperatures, and pollutants in the environment. Certain types of pigments, such as organic pigments, are more prone to fading than others.

To prevent fading, it is important to use paint that is designed to resist fading, such as paint with UV inhibitors, and to properly prepare the surface before painting. If fading does occur, the affected areas may need to be repainted.

11 : Coating Faults and Paint Defect: Fish Eye

Fish eye is a paint defect that occurs when small, circular depressions appear on the surface of a painted object. This can be caused by the presence of contaminants on the surface, such as oil, silicone, or wax, which repel the paint and cause it to form into small droplets. Fish eye can also be caused by the use of incompatible paint or primer.

To prevent fish eye, it is important to properly clean and prepare the surface before painting, and to use paint and primer that are compatible with the surface. If fish eye does occur, the affected areas should be cleaned and the paint should be reapplied.

12 : Coating Faults and Paint Defect: Flaking

Flaking is a paint defect that occurs when small, thin pieces of paint peel or flake off the surface of a painted object. This can be caused by a variety of factors, such as improper surface preparation, the use of an incompatible paint or primer, or exposure to moisture or extreme temperatures.

To prevent flaking, it is important to properly prepare the surface before painting, and to use paint and primer that are suitable for the specific conditions of the environment. If flaking does occur, the affected areas should be sanded down and repainted.

13 : Coating Faults and Paint Defect: Flotation and Flooding

- Flotation

- Flooding

Flotation, also known as floating, is a paint defect that occurs when a paint has been incorrectly formulated with two or more different colored pigments. When one of the pigments floats to the surface, it gives the appearance of different color variations. On close examination, the surface appears mottled with regular shaped cells.

To prevent flotation, it is important to properly mix the pigments and ensure that the paint is formulated correctly. If flotation does occur, the affected areas may need to be sanded down and repainted.

Flooding is similar to flotation in that one of the pigments migrates to the surface when the paint is produced using two pigments with different densities. This can give the surface a mottled or uneven appearance.

To prevent flooding, it is important to ensure that the pigments used in the paint are of similar densities, and that the paint is formulated correctly. If flooding does occur, the affected areas may need to be sanded down and repainted.

14 : Coating Faults and Paint Defect: Gassing

Gassing is a paint defect that occurs when bubbles or blisters form on the surface of a freshly painted object. This is caused by gases, such as air or solvent vapor, becoming trapped in the paint film as it dries. Gassing can be caused by a variety of factors, including improper mixing or application of the paint, or the use of paint that is not suitable for the specific conditions of the environment.

To prevent gassing, it is important to properly mix and apply the paint, and to use paint that is suitable for the specific conditions of the environment. If gassing does occur, the affected areas should be allowed to dry completely and then sanded down before repainting.

15 : Coating Faults and Paint Defect: Mould

Mould is a paint defect that occurs when mold or mildew grows on the surface of a painted object. This can happen due to a variety of factors, such as exposure to moisture, high humidity, or poor ventilation. Mould can also occur when paint is applied to surfaces that are not properly cleaned or prepared.

To prevent mould, it is important to properly prepare the surface before painting, and to use paint that is designed to resist mold and mildew. If mould does occur, the affected areas should be cleaned and treated with a mold inhibitor before repainting.

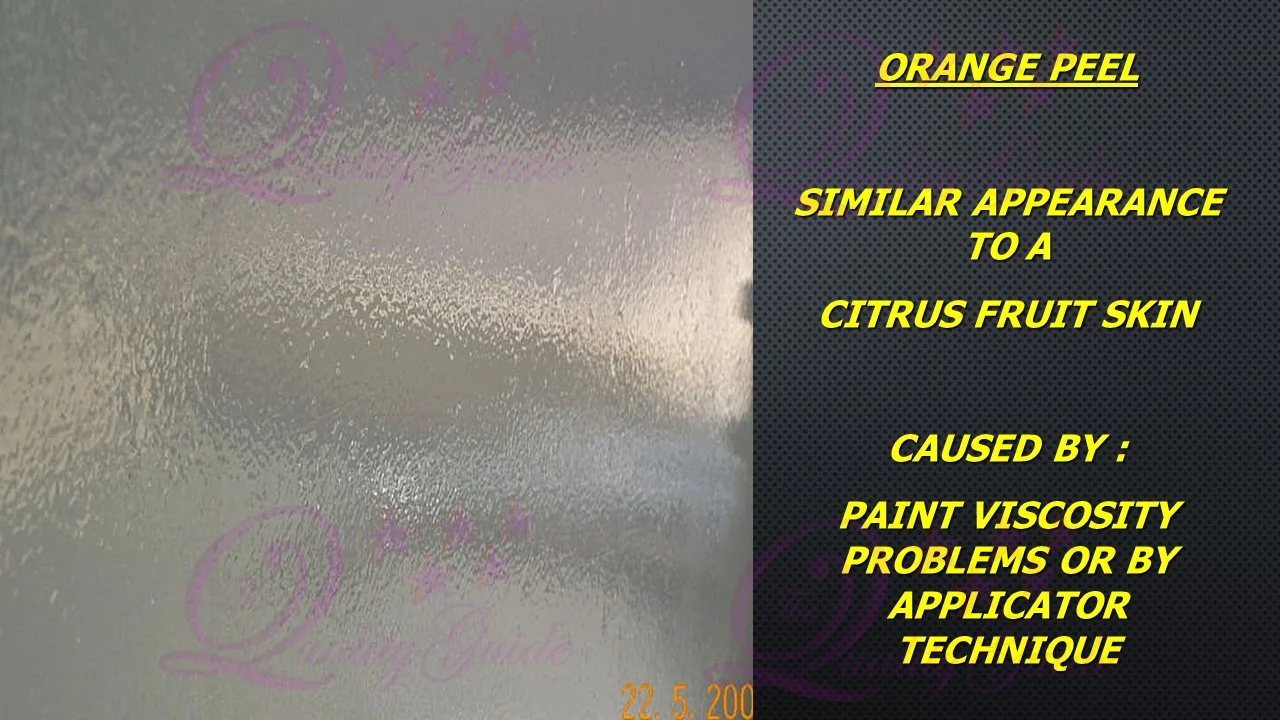

16 : Coating Faults and Paint Defect: Orange Peel

Orange peel is a paint defect that occurs when the surface of a painted object has a texture that resembles the skin of an orange. This is caused by improper application of the paint, such as applying the paint too thickly or not allowing sufficient time for the paint to dry between coats. Orange peel can also be caused by the use of paint that is not compatible with the surface being painted, or by the use of an incorrect type of spray equipment.

To prevent orange peel, it is important to properly prepare the surface before painting, and to use paint and primer that are suitable for the specific conditions of the environment. The paint should be applied in thin, even coats, and allowed to dry completely between coats. If orange peel does occur, the affected areas may need to be sanded down and repainted.

17 : Coating Faults and Paint Defect: Peeling

Peeling is a paint defect that occurs when the paint on a surface begins to lift and peel away from the underlying surface. This can happen due to a variety of factors, such as improper surface preparation, the use of an incompatible paint or primer, or exposure to moisture or extreme temperatures.

To prevent peeling, it is important to properly prepare the surface before painting, and to use paint and primer that are suitable for the specific conditions of the environment. If peeling does occur, the affected areas should be sanded down and repainted.

18 : Coating Faults and Paint Defect: Pinholing

Pinholing is a paint defect that occurs when small, round holes appear on the surface of a painted object. This can be caused by the presence of contaminants on the surface, such as dust or oil, which prevent the paint from adhering properly. Pinholing can also be caused by the use of paint that is too thick, or by improper curing or drying of the paint.

To prevent pinholing, it is important to properly clean and prepare the surface before painting, and to use paint that is the correct viscosity. If pinholing does occur, the affected areas should be sanded down and repainted.

19: Coating Faults and Paint Defect: Poor Flow

Poor flow is a paint defect that occurs when the paint does not spread evenly or smoothly on the surface, resulting in an uneven or rough finish. This can be caused by a variety of factors, such as the use of paint that is too thick, improper surface preparation, or the use of a brush or roller with the wrong nap length.

To prevent poor flow, it is important to properly prepare the surface before painting, and to use paint that is the correct viscosity. The paint should also be mixed properly and applied with the appropriate brush or roller. If poor flow does occur, the affected areas may need to be sanded down and repainted.

20 : Coating Faults and Paint Defect: Poor Hiding or Lack of Opacity

Poor hiding or lack of opacity is a paint defect that occurs when the paint does not adequately cover the surface, resulting in the underlying color or surface showing through. This can be caused by the use of paint with low opacity, improper surface preparation, or applying the paint in too thin of a coat.

To prevent poor hiding or lack of opacity, it is important to properly prepare the surface before painting, and to use paint with a high opacity level. The paint should also be applied in multiple thin coats, allowing each coat to dry before applying the next.

If poor hiding or lack of opacity does occur, the affected areas may need to be sanded down and repainted with a higher opacity paint.

21: Coating Faults and Paint Defect: Runs and Sags

- Runs

- Sags

Runs are a paint defect that occurs when the paint drips or runs down the surface of a painted object. This can be caused by the use of paint that is too thin, or by applying the paint in too heavy of a coat. It can also happen if the paint is not allowed to dry properly between coats.

To prevent runs, it is important to use paint that is the correct viscosity and to apply the paint in thin, even coats. The paint should also be allowed to dry completely between coats.

Sags are a paint defect that occurs when the paint droops or sags on the surface of a painted object. This can be caused by the use of paint that is too thick, or by applying the paint in too heavy of a coat.

To prevent sags, it is important to use paint that is the correct viscosity and to apply the paint in thin, even coats. The paint should also be allowed to dry completely between coats.

22 : Coating Faults and Paint Defect: Settling

Settling is a paint defect that occurs when the pigments in the paint separate and settle to the bottom of the container, resulting in an uneven color and finish when applied. This can happen when paint is stored for an extended period of time or when it's not properly mixed before use.

To prevent settling, it is important to properly mix and stir the paint before use, and to use the paint within a reasonable time frame. If settling does occur, the paint should be thoroughly stirred or remixed to redistribute the pigments, before applying.

23 : Coating Faults and Paint Defect: Slow Drying

Slow drying is a paint defect that occurs when the paint takes a longer time to dry than expected. This can be caused by a variety of factors, such as low temperatures, high humidity, the use of paint with a low solids content, or the presence of contaminants on the surface.

To prevent slow drying, it is important to use paint that is designed for the specific conditions of the environment, and to properly prepare the surface before painting. If slow drying does occur, the affected areas should be allowed to dry completely before applying additional coats or topcoats.

24 : Coating Faults and Paint Defect: Staining

Staining is a paint defect that occurs when the paint discolors or stains the underlying surface or surrounding areas. This can happen due to a variety of factors, such as improper surface preparation, the use of an incompatible paint or primer, or exposure to certain chemicals or substances.

To prevent staining, it is important to properly prepare the surface before painting and to use paint and primer that are suitable for the specific conditions of the environment. If staining does occur, the affected areas should be cleaned and the paint should be reapplied.

25 : Coating Faults and Paint Defect: Viscosity Drop

Viscosity drop is a paint defect that occurs when the paint becomes too thin and loses its consistency, making it difficult to apply and resulting in an uneven finish. This can happen due to a variety of factors, such as exposure to high temperatures, evaporation of solvents, or prolonged storage.

To prevent viscosity drop, it is important to store paint in a cool, dry place and to use it within a reasonable time frame. If viscosity drop does occur, the paint should be remixed or thinned to the correct consistency before applying.

26 : Coating Faults and Paint Defect: Wrinkling, Webbing, Frosting and Gas Checking

- Wrinkling

- Webbing

- Frosting

Wrinkling is a paint defect that occurs when the paint forms wrinkles or creases on the surface of a painted object. This can be caused by the use of paint that is too thick, or by applying the paint in too heavy of a coat. It can also happen if the paint is not allowed to dry properly between coats.

Webbing is a paint defect that occurs when thin strands or webs of paint form on the surface of a painted object. This can be caused by the use of paint that is too thin, or by applying the paint with a spray gun that is not properly adjusted.

Frosting is a paint defect that occurs when the paint forms a dull, frosted appearance on the surface of a painted object. This can be caused by the use of paint that is too thick, or by applying the paint in too heavy of a coat.

27 : Coating Faults and Paint Defect: Banding

Banding is a paint defect that occurs when the paint forms noticeable, repeating lines or bands of different colors or sheens on the surface of a painted object. This can be caused by the use of paint that is not properly mixed or stirred, or by using multiple batches of paint with slight variations in color or sheen. It can also be caused by using a roller or brush with an incorrect nap length or by not allowing sufficient time for the paint to dry between coats.

To prevent banding, it is important to properly mix and stir the paint before use, use paint from the same batch, use the correct roller or brush, and to allow sufficient time for the paint to dry between coats.

0 Comments