A visual assessment of a steel substrate can be performed as follows:

Inspect the surface for any visible damage such as scratches, dents, or corrosion. Pay particular attention to welds, corners, and edges as these areas may be more prone to damage.

- Check the surface finish of the steel. A smooth, uniform finish may indicate that the steel has been properly processed and handled, while a rough or uneven finish may indicate issues with the manufacturing process or handling.

- Look for any evidence of rust or corrosion on the surface of the steel. Rust or corrosion can weaken the steel and may require remediation.

- Check for any deformities or distortions in the steel. These may indicate that the steel has been subjected to excessive stress or has been improperly handled.

- Inspect the edges of the steel for sharpness or burrs. Sharp edges or burrs may pose a safety hazard and should be addressed.

- Check for any visible defects or imperfections in the steel. These may affect the structural integrity of the steel and may need to be addressed.

It is important to note that a visual assessment is only one step in evaluating the condition of a steel substrate. Other methods such as ultrasonic testing, magnetic particle inspection, and radiographic testing may also be necessary to fully assess the condition of the steel.

Visual assessment of surface cleanliness ISO Standards 8501-1; 2007.

According to ISO 8501-1:2007, a visual assessment of the cleanliness of a surface should take into account the following factors:

- Visible contaminants: Any visible contaminants on the surface, such as dust, dirt, oil, grease, or other foreign matter should be noted.

- Rust or corrosion: Any rust or corrosion on the surface should be noted, as it may affect the adhesion of coatings or other materials applied to the surface.

- Surface profile: The surface profile, or roughness, of the surface should be evaluated. A rough surface may be more difficult to clean or may require additional preparation before coating.

- Surface defects: Any visible defects on the surface, such as pits, cracks, or weld marks, should be noted. These defects may affect the adhesion of coatings or other materials applied to the surface.

- Surface preparation methods: Any surface preparation methods used, such as blasting or grinding, should be noted. These methods may affect the cleanliness of the surface and may need to be taken into account when evaluating the surface for coating or other applications.

It is important to note that a visual assessment of surface cleanliness is only one step in evaluating the suitability of a surface for coating or other applications. Other methods, such as solvent wiping or tape testing, may also be necessary to fully assess the cleanliness of a surface.

The British Gas Association (BGAS) is an organization that provides training and certification for professionals in the painting and coatings industry. If you are a BGAS-certified Painting/Coating Inspector and you need to remove rust from a steel surface, there are several methods you can use, depending on the severity of the rusting.

In the context of rust grading, a "Grade A" rating means that the steel surface has a minimal amount of rust, with most of the surface covered in mill scale. This is generally considered to be a relatively high-quality steel surface, as it has minimal corrosion and is relatively easy to clean and prepare for further processing or use.

For light rust (e.g., Rust Grade B), you can often remove it using a wire brush or sandpaper. You can also use a chemical rust remover, which can be applied to the surface and then washed off, taking the rust with it.

For moderate rust (e.g., Rust Grade C), you may need to use abrasive blasting, such as sandblasting or grit blasting, to remove the rust. This involves directing a stream of abrasive particles at the surface of the steel to remove the rust and any other contaminants.

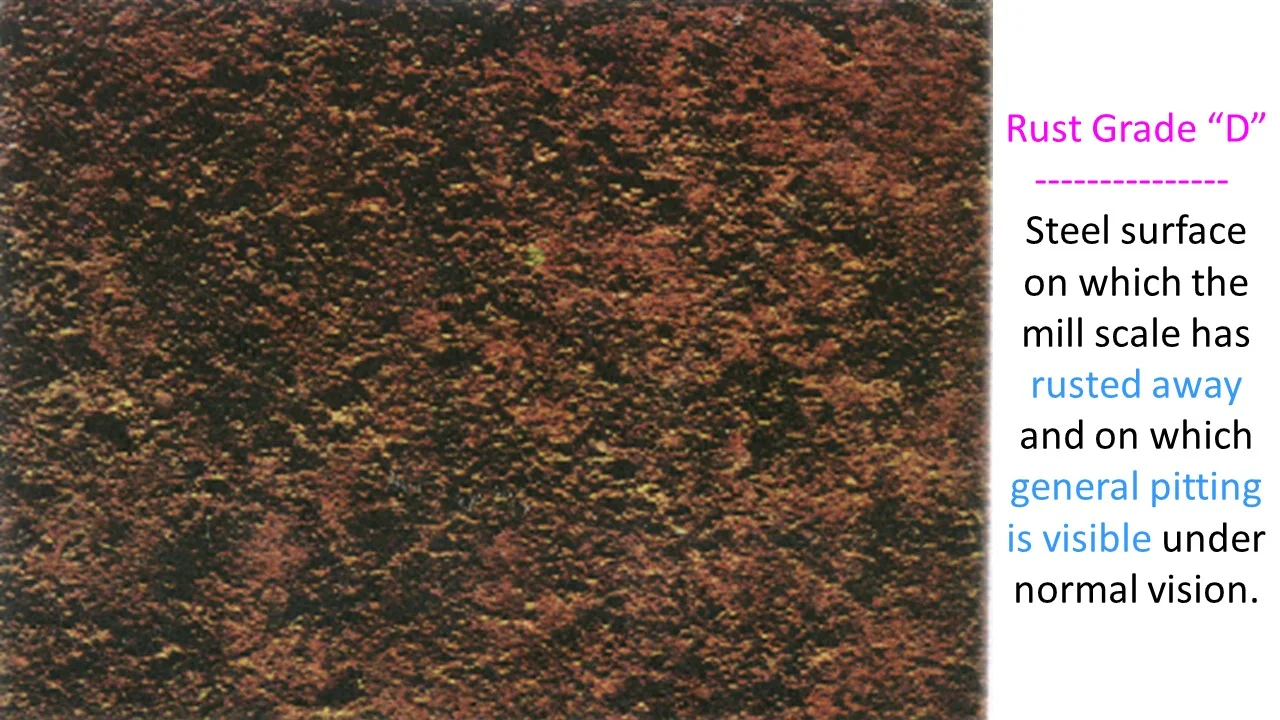

For heavy rust (e.g., Rust Grade D), you may need to use more aggressive methods, such as grinding or welding, to remove the rust. It is important to exercise caution when using these methods, as they can generate heat and sparks that could be dangerous.

It is also important to follow proper safety procedures when working with rust and steel, including wearing protective equipment such as goggles, gloves, and a respirator.

0 Comments